ECS offers the only In-Vessel Tunnel-type composting system developed and built in North America. This technology offers the ultimate compost tool for odor and emission control, leachate control and management, challenging feedstock management, and cold weather performance.

Their sealed, well-drained, and highly controlled aeration allows them to reliably manage less-than ideal feedstock mixes without creating nuisance odors. Their unique level of thermal control provides rapid heating of cold loads to very uniform temperatures throughout the pile to insure the Process to Further Reduce Pathogens (PFRP) is quickly and reliably achieved. Additionally, the robust design and construction of ECS’ In-Vessel Tunnels means that they last for decades.

The ECS in-vessel composting system can work well for facilities that are odor sensitive, have challenging feedstocks, and/or need weather-proof rapid bio-stabilization rates. This system is an ideal choice when composting operations must be fully enclosed as it minimizes both the facility footprint and greatly reduces the volume of room air that must be handled, heated, exchanged, and scrubbed. Because the vessels are fully enclosed, a bio-layer cover is not required, which keeps operational costs very low. Combined with using our ADT service to optimize a retention time, in-vessel composting can achieve very rapid rates of stabilization in a short period of time (often a couple weeks)

The vessels are made of concrete that is either site-poured or panelized. Vessel sizes vary to conform to the client’s site and process. The vessel walls and ceilings are well-insulated; doors are fully gasketed, weatherproof, and insulated. All door surfaces exposed to the process air are stainless steel or FRP. The aeration floor provides uniform air distribution and collects condensate/leachate to a sealed sump.

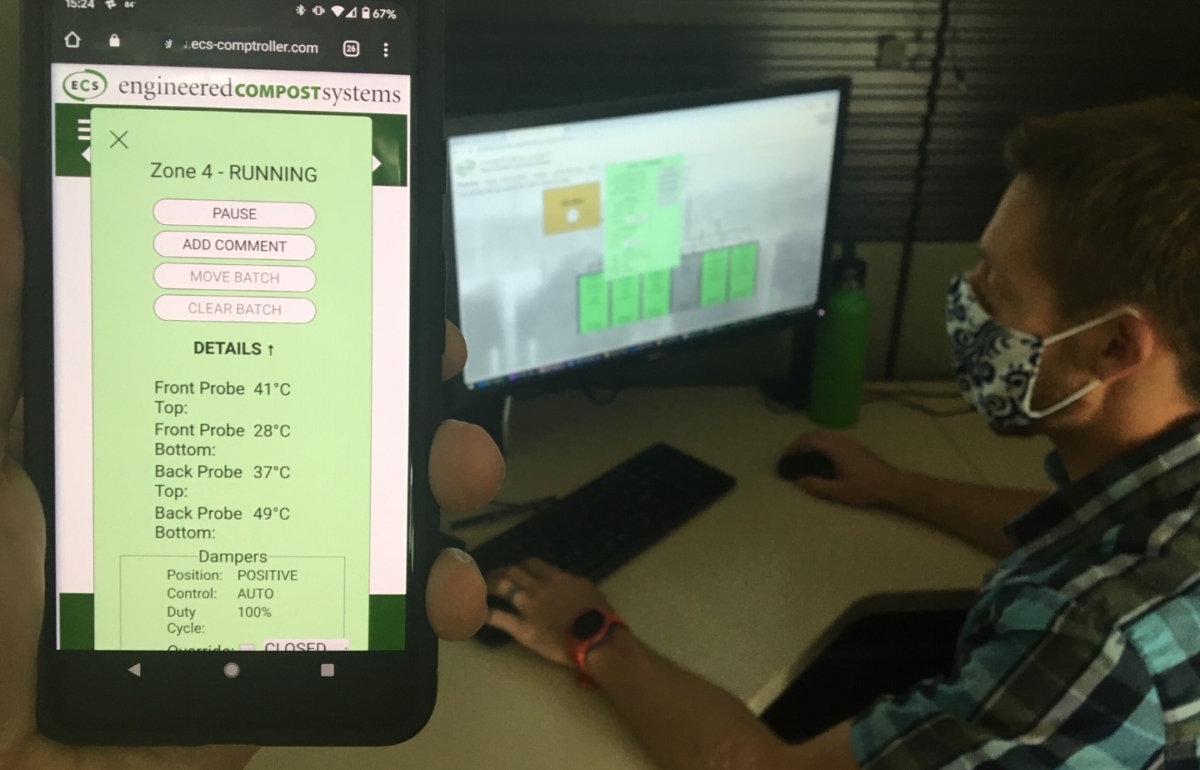

The aeration system provides very high flow rates of recirculating process airflow to control and maintain uniform BMP compliant temperatures and oxygen levels. Process air is exhausted through an ECS designed biofilter. All components in contact with the compost’s corrosive airstream are made from either stainless steel or HDPE materials. The aeration system is designed to conserve energy with variable speed fans, minimizing the retention time required, and adaptive control strategies. Motorized dampers control airflow to each vessel. Damper positions are automatically set by the control system in real-time based on temperature feedback.

ECS’ CompTrollerTM is an automated aeration control and monitoring system that operates at all ECS compost installations. It is designed to achieve regulatory compliance; offers operators a broad range of process options; and provides each vessel with independent and automatic control for achieving process goals. The CompTrollerTM is remotely accessible via the web and is flexible, robust, and keeps your data safe.

We want to learn more about your project goals. Call or email us to get started.