acf domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /nas/content/live/ecs2021/wp-includes/functions.php on line 6121ECS aerated static pile (ASP) compost systems provide an efficient tool to minimize odors and make great compost. Our systems feature dynamically controlled aeration with a wide range of air delivery rates required to keep oxygen and temperature optimized throughout the pile. At the same time, our systems incorporate energy efficeint duct design and fan selection, to help minimize operating costs. Our dedication to continuous improvement has led to ASP designs that simplify construction, provide uniform distribution of air, are uniquely effective at controlling leachate, facilitate maintenance, simplify operations, and will run reliably for decades. ECS aerated static pile composting come in positive, negative, and reversing aeration systems; bunker-wall, mass-bed, and in-vessel configurations; and are designed to best fit your site, feed stocks, and economics.

ECS aerated static pile systems (ASP) can offer the following standard features depending on your operation needs:

The aeration system distributes air through the biomass to optimize composting conditions. All process air exhausts through a biolayer cover or ECS designed biofilter. All aeration components in contact with the compost’s exhaust air-stream are corrosion resistant. The aeration system is designed to conserve energy with variable speed fans, and adaptive control strategies. Motorized dampers control airflow and direction to each pile. Damper position is automatically set by the control system.

ECS offers several different below and above grade aeration floors that distribute air through the biomass and are compatible with loading and unloading using front-end loaders. Our below-grade trench and sparger pipe aeration floor collect condensate/leachate, are plug-resistant, and are designed with ease of construction and maintenance in mind.

ECS’ CompTroller™ is an automated aeration control and monitoring system that is operating at all ECS compost installations. It is designed to achieve regulatory compliance; offers operators a broad range of process options; and provides each pile/zone with independent and automatic control for achieving process goals. It allows the operator to set aeration rates very low (anoxic conditions) if conserving moisture and fan power is the highest process-setting priority; or higher to reduce temperature and increase drying rates. The CompTroller™ is remotely accessible via the web and is flexible, robust, and keeps your data safe.

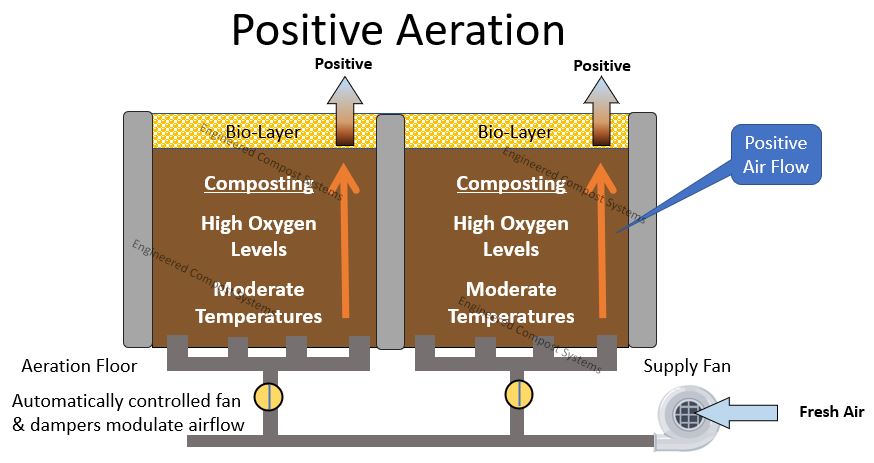

Positive aeration is the simplest approach for forcing air through a pile. The fan draws in ambient air and pushes it through the ductwork, into the aeration floor and up through the pile. As the air moves through the pile delivering O2 to the microbes, it picks up heat and moisture before exiting at the pile surface. With most positive aeration systems, the biolayer cover helps provide some scrubbing before the process air mixes with ambient air. Due to the mechanical simplicity and lower corrosive exposure, positive aeration tends to cost less than other options.

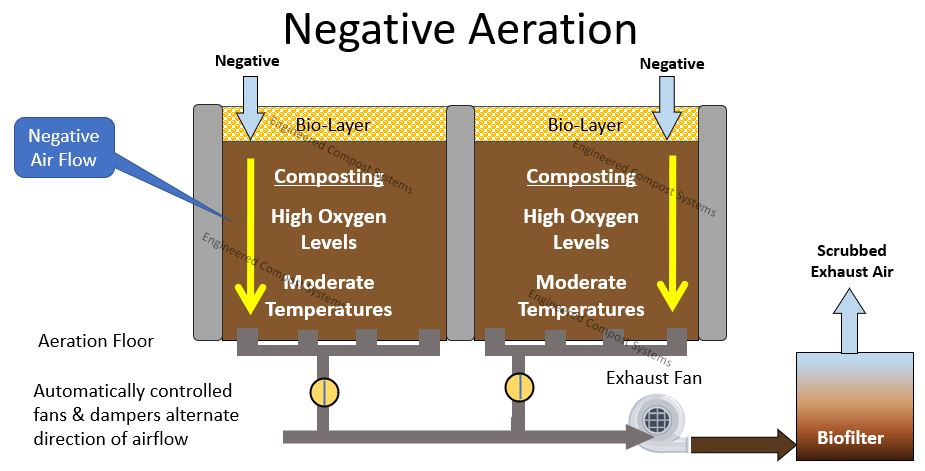

Negative aeration draws air through the pile surface, down through the floor, out of the exhaust fan and into a biofilter. Since the duct must withstand both implosion and corrosive process air, it requires higher design rigor than duct in a positively aerated system. This typically means higher duct pressure ratings and stainless rather than mild steel surfaces. In addition, sucking air through the floor can increase orifice plugging, and works better with trench style floors rather than above or below grade pipe. The biofilter scrubs the process air before exhausting it, providing significantly reduced emissions compared to positive aeration systems.

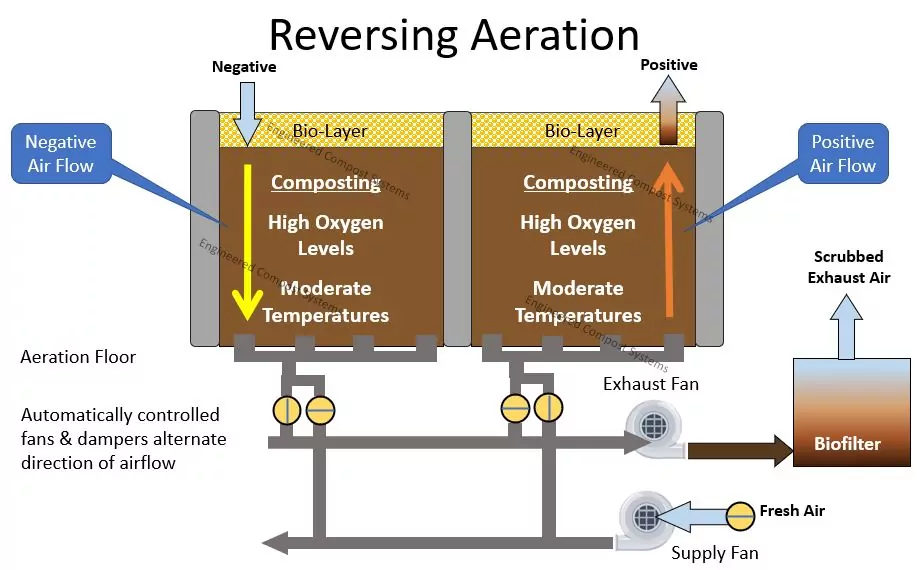

Reversing aeration alternates the direction of airflow through the pile by opening and closing dampers connected to the supply and exhaust fans. Alternating the air direction provides the tremendous process advantage of reducing the thermocline, or temperature gradient, through the pile. A more uniform temperature between the top and bottom of the pile results in better control, less risk of cold spots and pathogen survival, and much faster composting. Reversing aeration offers some of the biofiltration benefits of negative aeration, along with the plugging resilience of positive aeration.

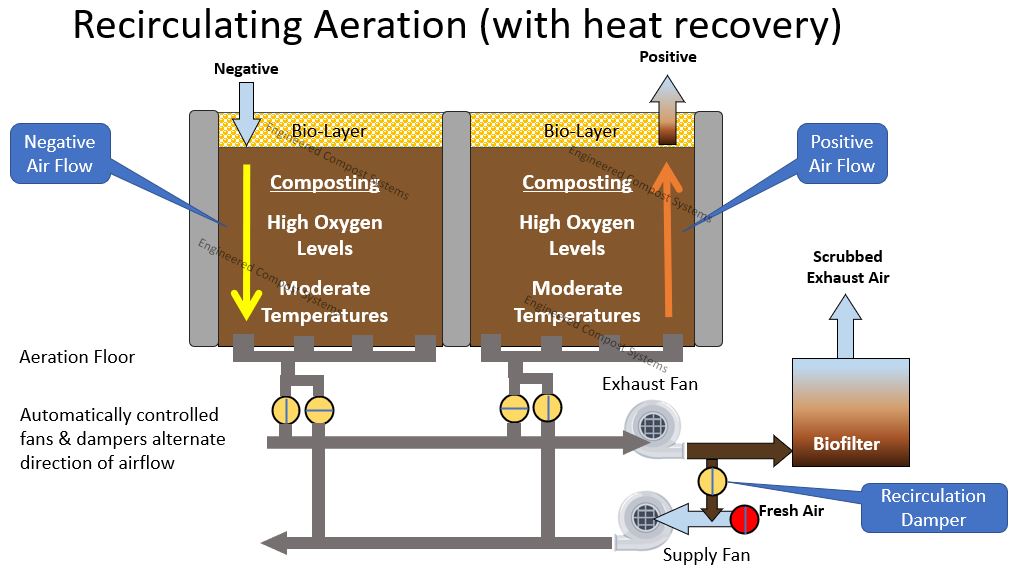

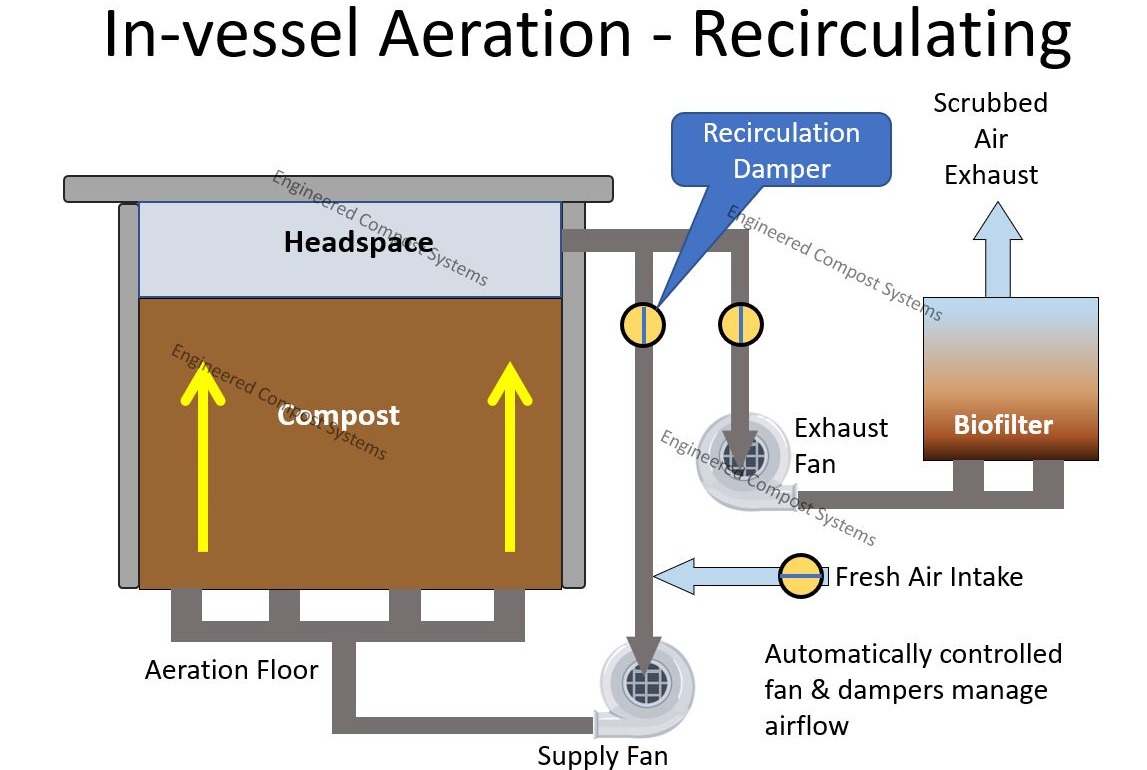

Recirculating aeration works well in cold weather environments that require rapid composting despite seasonal temperature swings. The recirculation damper allows warm air from the exhaust plenum to flow into the supply fan – recovering some of this thermal energy. During warm conditions when more cooling is required, the recirculation damper can be closed. While this approach typically requires more expensive stainless steel duct for both exhaust and supply air streams, the shortened retention times from improved cold weather performance can often balance out this cost.

Recirculating aeration is one of several aeration strategies for in-vessel composting. This approach pushes air in a single direction through the floor – often enabling the use of lower-cost below grade pipe flooring. In addition, the recirculation helps maintain an even temperature throughout the pile (minimal thermocline). As the microbes consume oxygen, the dampers allow more fresh air to enter the system and exhaust air to exit through the biofilter. For very cold climates, recirculating warm air between zones can help speed up a cold fresh batch of material. While the additional mechanical and concrete complexities of in-vessel systems lead to higher costs, these systems offer superior process control and excellent odor and surface water management with a wide range feedstocks and climates.

We want to learn more about your project goals. Call or email us to get started.