Composting is an important process that municipalities should consider implementing as part of their waste management strategy. Successful composting of food waste and other organic materials can be challenging, especially when dealing with large quantities of waste and adhering to multiple regulations and air emissions standards. However, the benefits of composting at a commercial scale make it a worthwhile investment.

One of the primary concerns with composting is odor. Composting can produce unpleasant odors, which can be a nuisance to nearby residents and businesses. This is why it is crucial to implement measures to ensure low-odor composting. Engineered Compost Systems (ECS) has extensive experience in developing low-odor composting operations around the world. By following the right process and using appropriate equipment, organic residuals can compost without creating odors that offend the neighbors.

Check out our presenation at the NY Organics Summit outlining these strategies:

In this post, we look specifically at odors caused from food waste composting to see how we can apply the latest compost science to keep our neighbors happy.

As municipalities increase organics diversion, acidic food waste concentration tends to increase at compost sites as well. The first few days and weeks of composting is the most critical time for any compost process, but especially when composting food waste. Before the pile has a chance to heat up (can start happening within 24-72 hours, depending on the feedstock energy and ambient conditions), it must be highly aerated to maintain cool temperatures. Cooler temperatures enable mesophilic bacteria to transition the pH level from acidic (4-6) to neutral (>6.5). This transition enables process conditions for the higher temperature (thermophile) microbes to thrive and compost efficeintly.

It’s not that passively aerated piles—that is, turned windrow and/or unaerated static pile systems—do not make compost; they are just far less efficient (much slower). Without forced aeration, only the surface ~8-12″ gets fresh O2, leaving the pile interior anaerobic. In addition, lack of forced air results in these piles often heating up quickly. Between high temperatures and anaerboic conditions, we see significantly more odorous gasses formed with windrow systems. Unaerated or poorly aerated systems starve the microbes of oxygen and create anaerobic conditions. For applications where odor control is a priority, aerated compost systems with automated temperature control offer superior performance.

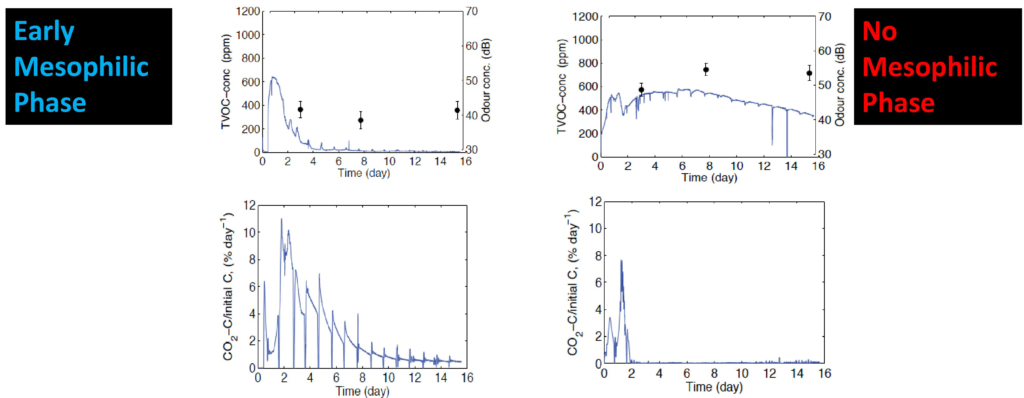

With an early mesophilic stage (high aeration, well controlled temperatures), the mesophilic microbes help raise the feedstock pH. This enables subsequent thermophilic microbes to work very efficiently. Teamwork!

The graphs on the left show a small initial spike in volatile organic compounds (VOC), which correlates to odor, followed by almost negligible levels. In addition, we see a very high sustained CO2 release (sign of rapid bio-oxidation!)

Conversely, the graphs on the right shows material that heats up quickly and skips the mesophilic stage. The pH remains acidic, which inhibits the thermophilic microbes. This results in sustained VOCs/Odors. In addition, we see very little CO2 activity. While this pile may be ‘cooking’, it is NOT composting. The resulting product will stink, have a very low pH, and will have achieved very little stability (commonly measured by CO2 respiration).

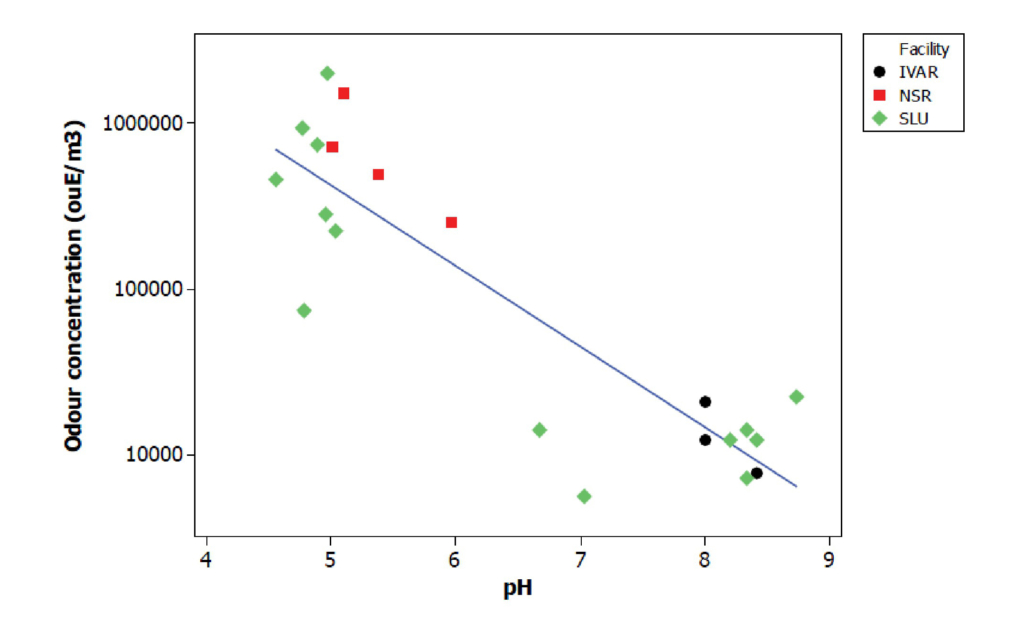

pH has been shown to be the key process indicator in predicting lifecycle odors when composting acidic feedstocks. As measured in work by Cecilia Sundberg , we consistently see sites with low pH achieving a 20-100x higher rate of odor generation than sites with neutral pH feedstock. The highly aerated mesophilic stage is the key to neutralizing the pH and avoiding excessive odors.

Again – the key to low odor commercial composting: manage the composting process conditions!

The best composting system to minimize odors is one that prioritizes effective aeration, as odors are primarily caused by the buildup of anaerobic microorganisms that produce volatile compounds. Therefore, a composting system that provides sufficient oxygen to the microorganisms can help to minimize unpleasant odors. A well-designed forced aeration composting system provides adequate cooling to maintain temperatures throughout the majority of a compost pile. This thereby enables aerobic bacteria to efficiently bio-oxidize feedstocks while minimizing the creation of odorous compounds.

In addition to low odor generation, we can also apply biofilter technology to further reduce odors. This may include: negative, reversing, or in-vessel aerated composting.

ECS offers the only In-Vessel Tunnel-type composting system developed and built in North America. These in-vessel compost systems have the ability to capture all of the exhaust air through a biofilter. In addition, they can recirculate airflow. This crease a more uniform temperature gradient through the pile for improved biodegredation. While there is a big range of approaches that may work at a given customer site, in-vessel composting is a powerful tool for facilities that are odor-sensitive.

Engineered Compost Systems has a unique set of scientific skills, air emissions data, and sampling and analysis tools to allow operators to comprehensively manage air emissions. Our systems have been recognized for their superior odor control, and we have the ability to quantify emissions by conducting sampling at a facility’s current process, or from a pilot facility.

Not up and running yet? If your facility is only in the planning phase, ECS has an extensive database to provide a most likely range of emissions to help remove the guesswork. We can provide odor analysis and dispersion modeling to quantitatively predict the odor impact from operations.

Need help determining what type of composting system you’ll need to meet local air emissions regulations? Wondering if what you’re planning to build will pass the sniff test? Contact us today.

We want to learn more about your project goals. Call or email us to get started.