The State of Minnesota is increasing its diversion efforts and recognizes that composting organics offers a viable, sustainable and long-term solution. In response Pope/Douglas Solid Waste Management (PDSWM) selected ECS technology to provide a bio-Covered Aerated Static Pile (CASP) composting system to process organics at their Glacial Ridge Composting Facility. The Glacial Ridge facility serves as a regional organics tipping floor and transfer station. With this expansion, PDSWM adds a new forced aeration compost process to manage current and future growth of their organic recycling.

This project offers a great case study of how a rural municipality can set up an organics collection program, and efficiently deploy capital to manage the evolving compost capacity requirements.

PDSWM offered several challenges for the ECS design/project team to tackle. These included a feedstock forecast with initial low collection volumes followed by large forecasted growth, and very cold winter weather composting conditions. Both of these challenges are very common for municipalities who launch new organics programs

To address the anticipated low starting volumes and help reduce the facility’s initial cost ECS proposed a CASP design that facilitates:

The initial aeration design features positive-only aeration system. The system and ductwork design accommodates a future reversing-aeration and biofiltration expansion. This strategy aims to optimize appropriate system technology based on current projected need.

For example, there is no doubt that the anticipated food waste and source separated organic feedstocks are challenging and require a high degree of odor control. However, based on the low initial volumes as the project starts, a positive aeration system is sufficient to maintain favorable process conditions and manage process odors. (Note: For the Phase 1 positive system ECS is including additional retention time to allow for slightly slower composting with single direction aeration during harsh winter conditions.)

Then, as the incoming volume of feedstocks increase, PDSWM can add a negative fan to the existing aeration system to enable reversing, recirculating aeration. Reversing aeration, which can push or pull air through the active pile, captures a large fraction of the process air directing it to a biofilter for additional odor and VOC reduction. The recirculation feature, which connects the warm exhaust air to the inlet of the positive supply fan, helps facilitate cold weather composting by conserving thermal energy.

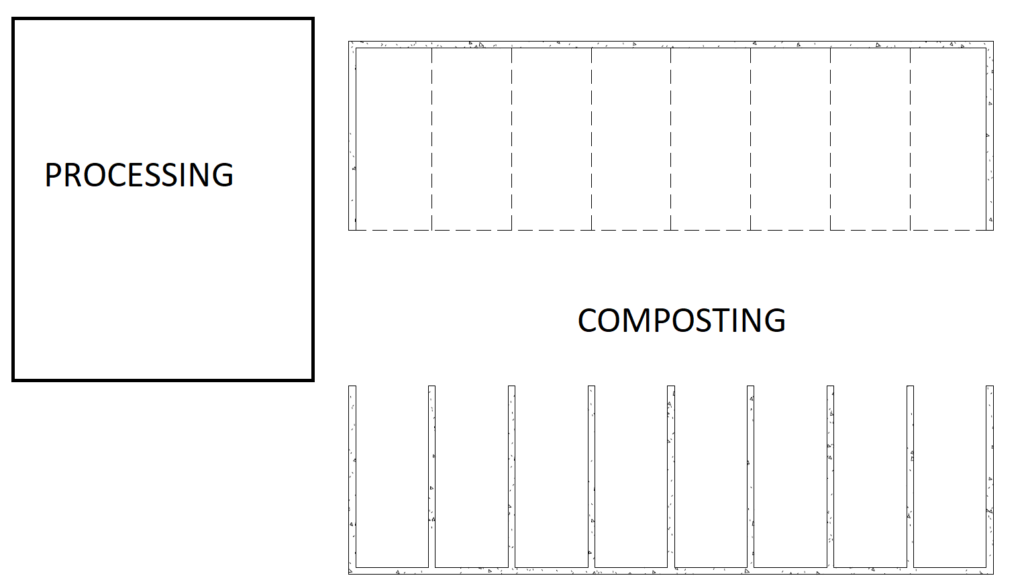

Using this phased design approach, which expands from 4 to 8 to 16 aerated zones, PDSWM will be able to choose the optimal time to add the additional capacity and avoid over-investing in infrastructure that is not yet needed.

For efficient sizing, the ECS system design allows for adding low cost upgrades to meet forecasted growth. For example, in Phase 1 ECS supplies the below grade infrastructure for future growth as part of the single concrete pour. The Phase 1 compost system includes 4 initial zones, fed by an aeration fan sized for the 8 zones of Phase 2. This approach helps minimize the life cycle system cost by keeping initial costs low and avoiding expensive major infrastructure costs by efficiently using the Phase 1 construction mobilization.

We look forward to sharing more on this project as it moves from construction to start up.

To learn more, check out the Glacial Ridge Website.