By Tim O’Neill & Geoff Hill

There is an increasing demand to compost commercial food waste. If done poorly, food waste composting can sour an entire city. If done well, composting is a sustainable way to recycle the organic matter and nutrients in this enormous waste stream. ECS has collected data from both failed and successful sites and, with help from scientific literature from Europe, we understand the fundamental and inescapable biological underpinnings that lead to sustainable, long-lasting programs. Read on to learn more or view our successful compost examples here.

There are a few simple Best Management Practices (BMPs) that can be performed regularly onsite at any composting facility and used as Key Performance Indicators (KPIs). With regular collection and an understanding of the target and range within each BMP, site operators can use the data to make immediate changes, predict emissions, and manage what will become a quality end product. The most effective time to collect data and adhere to BMPs (and use these as KPIs) is at the following stages:

This paper provides our recommendations for BMP data collection at these two stages, along with a short explanation of why these parameters are critical.

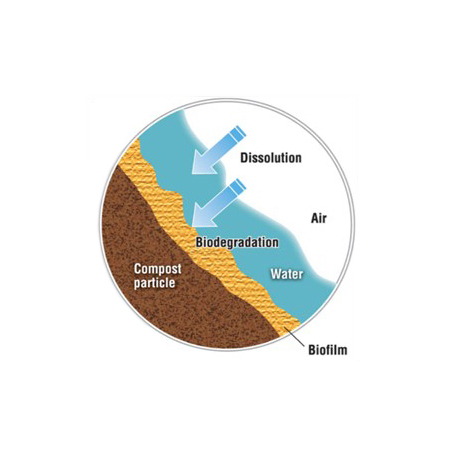

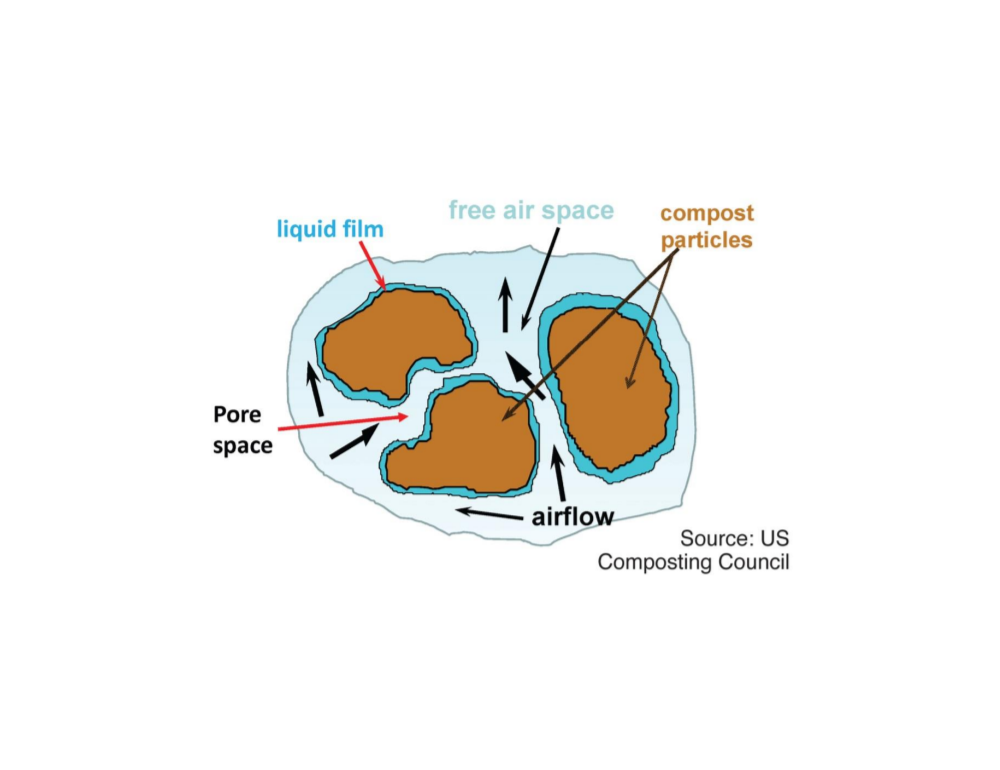

A BMP mix is critical to the entire compost process. There are three key parameters in a BMP mix: Moisture, density, and C/N ratio. These parameters set up proper conditions on the biofilm of decomposing waste particles, which is where all the ‘magic’ happens.

If all three parameters are within BMP ranges, the subsequent composting process will have the greatest chance of maintaining optimal process conditions. If one or more parameter falls outside the BMP range, the process will become inhibited and is likely to move into anoxic/anaerobic conditions, in which smelly by-product gases are produced and the process slows down dramatically.

The following table outlines the three mix parameters we think should be measured and logged regularly to assure a BMP mix is maintained in every batch of compost.

| Key Process Variable | BMP Target | Method | Frequency |

|---|---|---|---|

| Bulk Density | 750-1000 lb/cy | Bucket and scale | Composite sample each batch |

| Moisture Content | Moist not drippy | Squeeze test | 3-4 Grab samples each batch |

| Moisture Content | 52-63% | Lab test to verify squeeze test | Quarterly |

| C/N ratio | 25 | Lab test | Quarterly |

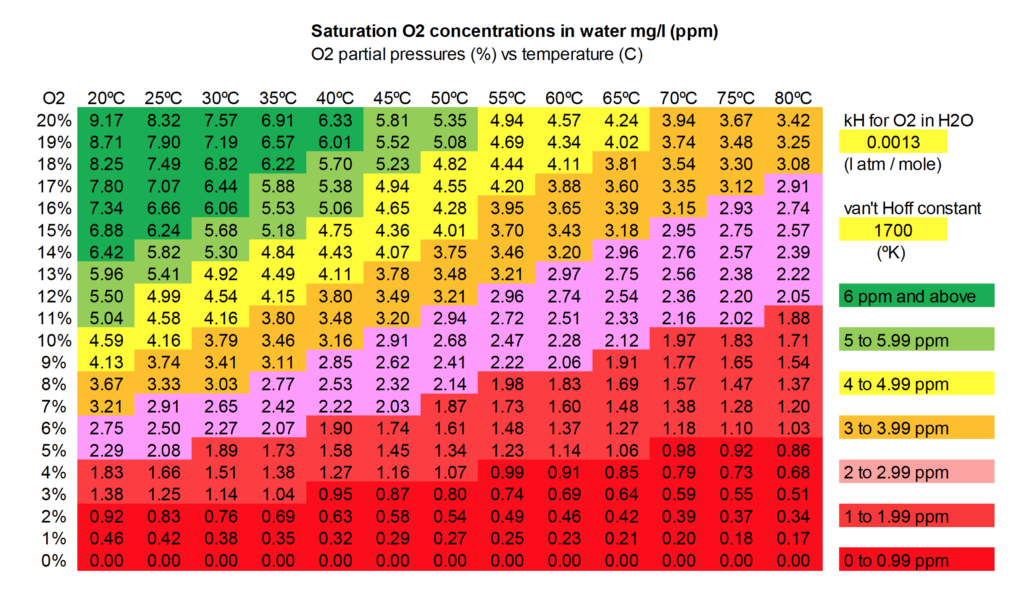

The first few days and weeks of composting is the most critical time for a compost pile, especially when composting food waste. Before the pile is allowed to heat up to Process to Further Reduce Pathogens (PFRP) temperatures, the pile should be highly aerated in order to change the pH from acidic (4-6) to neutral (>6.5). This is critical for low odor and rapid composting. Check out this peer reviewed research for more info. Beyond this early composting stage, the process should be controlled to have greater than 3 ppm oxygen at the biofilm of the compost particles (see table). The target process conditions to maintain 3 ppm are temperatures between 110°F and 150°F with average measured oxygen levels above 15%. If the pile is allowed to sustain temperatures above 150°F with average pore space oxygen levels below 15%, the process will emit excess odors, stabilization rates will slow, and the compost quality will suffer. In forced aeration systems, excessive temperatures are the result of inadequate airflow. Please see ECS Whitepaper: Forced Aeration Composting for more on the subject of aeration system design.

We want to learn more about your project goals. Call or email us to get started.