By Tim O’Neill & Aimee Manderlink

Organic meida biofilters are a common method of scrubbing process emissions and odors from composting and other biological and chemical processes such as from wastewater treatment plants. This paper provides a brief background on how biofilters work, specifically related to composting, and outlines key elements in their design and operation that determine their efficiency.

Biofiltration is a proven, cost-effective method of scrubbing odorous and volatile organic compound (VOC) rich air exhausted during industrial processes such as composting or often organic tipping/recieing buildings. Odor complaints and VOC levels above those permitted by local air quality standards can shut down a composting operation. A well-maintained biofilter can reduce the odor and VOC concentration by well over 90%. The following sections include ECS’ recommendations for constructing, operating, and maintaining a biofilter.

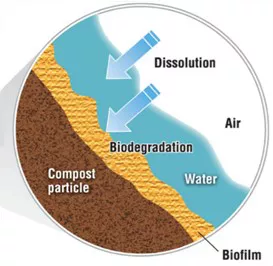

Figure 1 depicts the watery biofilm on the surface of a compost particle. Biofilter media (usually coarse wood chips) can also be wetted and therefore have a biofilm. As is the case in the composting process, the biochemical conditions in the biofilm on the media are critically important to the biofilter’s performance, or scrubbing efficiency.

A biofilter absorbs volatile compounds from the exhaust air stream into the biofilm layer. The biofilm, rich with aerobic bacteria and other microorganisms (aerobes), bio-oxidizes (consumes) the absorbed compounds, releasing energy and/or essential nutrients, such as nitrogen in ammonia (NH3), which are necessary for cellular maintenance and division. The following conditions in the media determine the efficiency of the aerobes:

When these conditions are maintained within a reasonable range, biofilters very efficiently oxidize a broad spectrum of volatile chemicals present in modest part-per-million concentrations common to compost exhaust air. The rule-of-thumb for the minimum scrubbing efficiency for an average biofilter is at least 90% on most compounds/odors found in composting exhaust air.

The rule-of-thumb scrubbing efficiency for ammonia is lower, and generally considered to be 75%. Semi-optimized composting conditions further reduce VOCs and odor generation by 50-90% compared to classic composting conditions. By pairing a well-designed composting facility and with an effective biofilter, air emissions can be dramatically reduced compared to industry norms.

The specifications for biofilter design depend on the types and concentrations of the compounds to be scrubbed in the exhaust air, the climate, and the site’s sensitivity to either odor generation or regulated VOC and NH3 emissions. Table 1 lists a typical range of biofilter design specifications.

| Specification | Typical Range of Values |

|---|---|

| Empty-Bed Residence Time | 15 – 60 seconds |

| Media Temperature | 40° – 120°F |

| Media pH | 5.5 – 8.5 |

| Active Media Depth | 36” – 72” |

| Media Moisture Content | > 50% |

| Initial Pressure Drop Thru Fresh Media | < 0.25” wc/foot of depth |

| Max Pressure Drop Thru Aged Media | < 1.0” wc/foot of depth |

| Dry Media Density (assuming wood) | < 600 lb/yd3 |

| Main Media Screen Size | 2”+ |

| Base Layer Screen Size | 4”+ |

| Base Layer Depth | 12” – 24” |

When building the biofilter, the media choice and preparation is key to all performance metrics including: scrubbing efficiency, fan power consumption, and media longevity. A bed of relatively coarse, stable media with a base layer of

When building the biofilter, the media choice and preparation is key to all performance metrics including: scrubbing efficiency, fan power consumption, and media longevity. A bed of relatively coarse, stable media with a base layer of coarser media will provide more uniform flow, higher surface area, lower friction loss, and a longer lifetime than a bed of finer degradable media. Good quality media should last from two to four years and this lifetime can often be extended by adding an additional one to two feet of media over the top of the bed once the media depth has dropped appreciably.

When preparing the media, a very small amount (1-2% by volume) of more degradable fines, such as compost, can be added to the otherwise coarse, clean shredded wood. The primary reason for adding compost to the media is to shorten the biological conditioning period by allowing the biofilm of the media to be thoroughly colonized by microbes. This colonization will happen with, or without the additions compost, just more slowly (we estimate the difference at a few weeks versus a few months).

ECS recommends the following media preparation procedure:

The media should be placed in sections that are small enough to allow the base layer to be laid down, then the wetted media layer to be added over the top without driving on the base layer. If placing material with a conveyor, or an extended reach machine, large sections can be constructed at one time. If placing material with an smaller excavator or wheel loader, the reach of the machine will limit the width of the section that can be built at one time. Once the base layer is placed, carefully place wetted media on top up to the initial design depth. Compression limits the useful life of the media; never drive on top of the media with a machine. If a uniform top surface is desired, hand raking is almost always required.

Maintaining the correct moisture content in the filter media is an important operational factor for a biofilter. The compost site operator should maintain the media above 45 percent moisture (see the following section). Media that becomes too dry will inhibit microbiological activity, reduce absorption, and thus be less effective at bio-oxidizing odorous gases. Assuming the media is porous, it is quite difficult to error on the higher end of moisture content (>65%) as the media will drain well and not hold the water. However, if the media has significantly degraded, it may absorb more than 65% moisture. The potential for the media to channel or crack also increases with age. This allows air to move faster through drier passages causing further localized drying and shrinkage of the media, reducing overall performance. Once this occurs, the operator should add additional media. The operator should change the media when it begins to visibly degrade, densify, and crack.

The exhaust air from a composting process is generally saturated (100% relative humidity, or RH). This is not true for building exhaust air. An airstream with 100% RH will constantly deliver moisture to the majority of the media as it cools The exhaust air from a composting process is generally saturated (100% relative humidity, or RH). This is not true for building exhaust air. An airstream with 100% RH will constantly deliver moisture to the majority of the media as it cools when passing through the bed. If a significant volume of building exhaust air is to be included, then an in-line humification system should be considered. Even when fed with moist exhaust air, the upper layer of the media will often appear dry due to evaporation to ambient air. This generally does not strongly impact the overall performance. Adding irrigation to the surface or within the media can improve performance, especially in dry hot environments. This can be done by either placing tight-spaced soaker hoses at the top of the pile or using surface sprinklers. Irrigation can have the added benefit of washing out soluble nitrates that can build-up in the media (especially while composting biosolids).

Temperature of the biofilter media is another important operational parameter. Biofilters applied to hot compost exhaust air typically have a significant vertical thermocline from the higher inlet temperatures to cooler ambient temperatures near the top surface. Per Henry’s Law, the lower the temperature of the liquid water layer (Figure 1), the more gaseous compounds will be absorbed. On the other hand, the metabolism of the bacteria that bio-oxidizes the VOCs peaks at round 150°F. Depending on the chemical and hydraulic loading rates, and compounds to be scrubbed, some lab-scale research has identified optimum media temperature to both absorb and bio-oxidize VOCs to be about 113°F (45°C). As the temperatures drop the scrubbing efficiency is very slowly reduced, but continues to scrub down to temperatures approaching freezing. As temperatures rise scrubbing efficiency slowly decrease up to about 131°F (55°C) but then drops off sharply by a temperature of 149°F (65°C). In practice there is no reason to be concerned with too low of media temperatures, other than freezing, since studies have shown that of VOC concentrations in compost exhaust drop sharply with decreasing temperature. But the high temperature can be problematic. For VOC and odor control, ECS recommends keeping peak temperatures under 130°F and average temperatures below 120°F.

Another reason for limiting high temperature is that the media itself will also degrade more quickly at temperatures above 130°F (a settled bed may lose a foot of depth in a matter of months if temperatures above 140°F are maintained). Short term excursions up to 130°F are acceptable so long as monthly average media temperatures are < 120°F. The compost aeration and control system should monitor, log, and control the temperatures of exhaust air and biofilter media. Ideally, the system will automatically control the exhaust air temperature to an operator chosen setpoint by adjusting the volume of added ambient air. If performance is critical, psychrometric (the thermodynamics of mixing air) and heat transfer calculations should be carried out to ascertain if additional humidification is required to prevent dilution air from over-drying the biofilter media.

The pH of the media can also impact both the scrubbing effectiveness and the nature of the odor emitted. Measuring the pH of media can be tricky since the pH is, by definition, an aqueous phase phenomenon. The loading rate, chemical spectrum, and the pH of the air stream and the irrigation water over time are typically the primary drivers of pH. As the pH changes, the biofilter scrubs different compounds with different efficiencies (acidic media better scrubs NH3 and mildly alkaline media best treats organic acids). ECS has measured the pH effect of VOC scrubbing efficiency of two identical biofilters at the same site. One biofilter had an apparent pH of 5.5 and an efficiency of 90% (factor of 10), and the second biofilter had a pH of 5.0 and a scrubbing efficiency of 80%. A few weeks later the second biofilter’s pH had risen to 5.7 and the scrubbing efficiency increased back above 90%. While pH is important, little can be done to change the pH of a biofilter in operation. Sustained low pH most likely indicates an inadequately managed composting process that is producing the low pH droplets that are depositing in the biofilter.

Even though biofilters are quite resilient to varying inlet and environmental conditions, there are several parameters a compost site operator should periodically monitor.

| Moisture | The operator should take grab samples from at least 12” deep in the media once every two weeks and perform the squeeze test to determine approximate moisture content. If the media appears to be over-drying, increase in-duct humidification (if present) and/or surface irrigation. |

| Temperature | Biofilter media temperatures should be recorded weekly if done manually, or hourly if integrated into the automated aeration control and monitoring system. If temperatures are excessive for extended periods of time (not just an occasional spike), the cooling air inlet damper should be adjusted to inject more ambient air into the biofilter duct. In some cases, increasing the rate of irrigation can also aid cooling. If the temperatures are too low, then adjustments should be made to the process control settings to increase the pile temperatures. These settings typically require seasonal adjustment. |

| pH | The operator should monitor the biofilter media pH monthly. If the pH is found to be out of the target range, then the condensate from the inlet air should be sampled and its pH measured. If that pH is out of the target range, then the composting process should be managed (by altering the mix or the process conditions) to adjust the inlet pH. The pH of the irrigation water should also be tested to determine if it helps or hurts the media pH. |

| Pressure Drop/Media Densification | The operator should record the static pressure drop through the biofilter at a standardized operating condition (the biofilter designer supplier should provide instructions). The pressure drop should be measured with the biofilter floor bare, then with new media, then once every six months to track densification in the media. |

| General Inspection | Woody biofilter media breaks down over time and will eventually require either an additional layer (if pressure drop is low enough) or replacement when: • There is visual cracking, channeling, and/or vegetative growth • The emission of odors or measured compounds from the biofilter surface markedly increases • Media depth drops below what is required for the EBRT design minimum When the media is replaced, the old media can be passed through a +2” screen and the overs can be reused in the new media mix. The balance of the material can be treated as compost.. |

We want to learn more about your project goals. Call or email us to get started.