We love collaborating with clients early in the process to explore and shape viable business models. This critical phase of project development helps set a clear vision for success—or sometimes reveals that a project may not be feasible. Either way, we provide valuable insights to guide informed decisions.

Our goal is to bring projects to life, but we prioritize honest assessments and strategic planning to ensure our clients move forward with confidence.

Thinking about expanding your compost operations? Let’s brainstorm together! Call us at 206-634-2625 or email [email protected] to get started.

Since 1999, ECS has worked with a wide variety of clients, in different geographies, with unique regulatory conditions, and a diverse array of feedstocks. Our first step in the feasibility process revolves around understanding the project drivers and discussion what success looks like. The following topics are frequently analyzed with our feasibility studies:

Some of the design feasibility and development services we offer include:

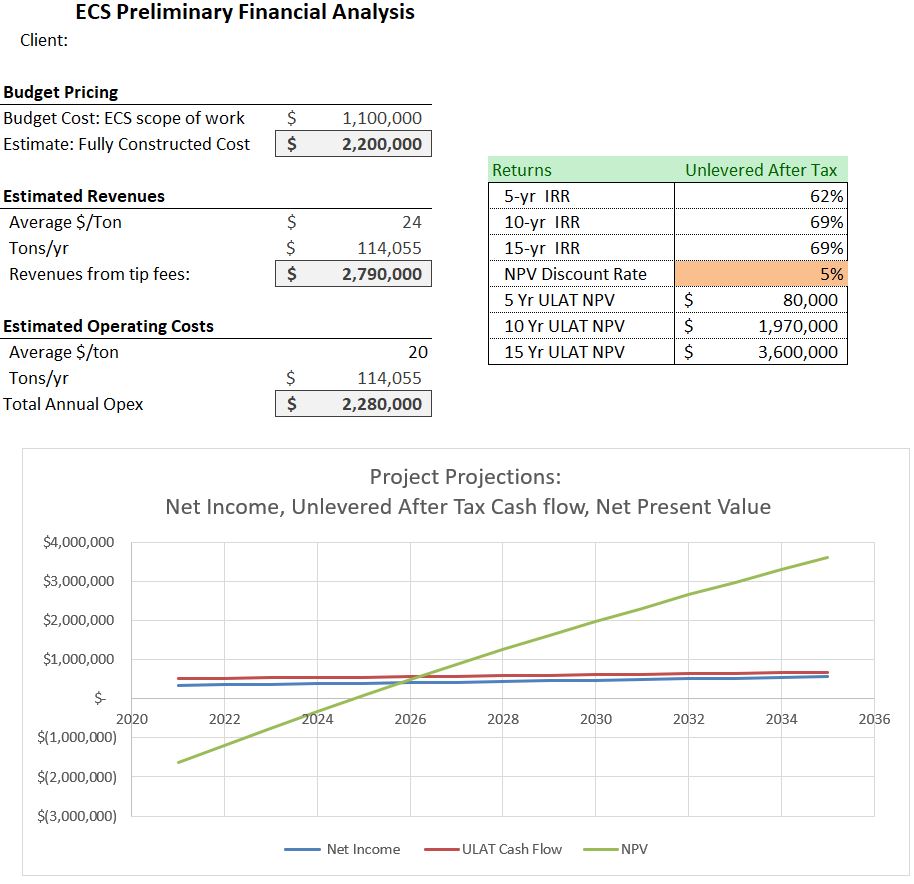

ECS offers a basic financial analysis service designed to help clients assess the feasibility of their composting projects. This tool facilitates collaboration on key assumptions and generates essential financial metrics, such as Internal Rate of Return (IRR) and Net Present Value (NPV), to guide decision-making.

By focusing on high-impact variables, this straightforward approach allows teams to model different scenarios and evaluate whether a project is viable. We’ve found this process especially valuable early on, as it helps determine if a project makes financial sense. If the business case is weak, this cost-effective tool can prevent unnecessary investment in a project that may not succeed. Conversely, more often than not, it helps align the team around a sound design strategy, keeping critical project variables front and center throughout the planning process.

The analysis greatly assists those that are new to the compost industry that are trying to determine if their unique application or opportunity has the solid foundation for a sound business; and, those currently in the compost industry that are trying to determine if a new process technology is appropriate (upgrading from windrow to in-vessel or ASP) and if so what type is appropriate.

Our Unique Approach

ECS offers our unique set of tools and skills to help both new and existing compost facility operators efficiently navigate an increasingly complicated terrain. As facility designers we are heavily involved in all aspects of planning, permitting, and designing. As technology and equipment providers we are immersed in the details of facility construction and start-up. In our technical support role we are the first call for most of our clients when any sort of process related issues arise. ECS engineers and scientists are constantly working with our loyal clients to help them measure and optimize their processes in response to changes in regulations, working environment and opportunities.

ECS approaches all our client’s challenges and opportunities with an open mind and a data-driven approach. Our “open mind” comes from working with clients who are succeeding with a wide range of composting methods. This has given rise to the ECS “Tool Kit” of process technologies which we configure to meet the unique needs of each facility. We use real process data to test performance claims, whether they are ours and by others. For years we have gathered data through our comprehensive compost control and monitoring systems, through our client support work, and from our own research. We use this data and rigorous first-principles modelling to predict process and economic performance.

Our Consulting Process

We typically begin with an efficient high-level economic and technical assessment of the issues and opportunities presented. This assessment provides the client with the information to further specify and/or reduce the number of options. From there we go only to the technical depth necessary to answer the key questions:

• What is the business case?

• What are the risks?

• What are the best process options?

Let us know about your composting opportunities and challenges. We look forward to helping you.

We want to learn more about your project goals. Call or email us to get started.