Compelled and concerned by the proliferation of compostable plastics in commercial compost feedstock streams, ECS developed a research plan to test certified compostable plastic degradation rates in our laboratory. On May 20th, Biocycle published an article detailing this research in depth. This post is a summary of our work and findings, which adds to the growing body of evidence about prolonged and problematic bioplastic degradation rates.

As certified compostable bioplastics began showing up at commercial compost facilities, we observed different compostable plastics break down at different rates. ECS analyzed whether PLA-based bioplastics were chemically different from one another, and if these chemical differences could be creating disparate degradation rates. As it turns out, a concept known as crystallinity may be a piece of the puzzle that composters are tasked with solving.

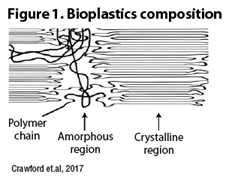

“Crystallinity” refers to the structurally ordered regions of a material; the degree of crystallinity suggests how orderly and tightly knit the polymer chains of a material are, and, fundamentally, how stable that material is in solid form. As the diagram in the figure below demonstrates, crystalline regions are more densely packed with molecules (Crawford et.al, 2017) and are less prone to brittleness under physical stress or heat than the amorphous regions.

Modern manufacturing technology has increased the degree of crystallinity in bioplastics. While crystallinity is important to a manufacturer, as more crystalline bioplastics hold up better in foodservice applications, it makes biodegradation more difficult. This is because in a composting environment, bioplastics degrade by a process called mineralization. Mineralization occurs when enzymes secreted by compost bacteria interact with bioplastics. The enzymes break the PLA polymers into smaller molecules, which are then consumed by the microbes for their survival (Zambrano et.al 2020). The more tightly-packed the PLA molecules are, the harder it is for microbes to mineralize them. As manufacturers design compostable products that are more resistant to biodegradation, they may also be making products that undermine the very solution they are designed to be.

In developing a research plan, we sought to correlate certain compost process conditions (temperature, moisture, oxygen, etc), with improved biodegradation. We hypothesized:

Phase 1 tested these three individual hypotheses, and Phase 2 refined hypothesis 3 further.

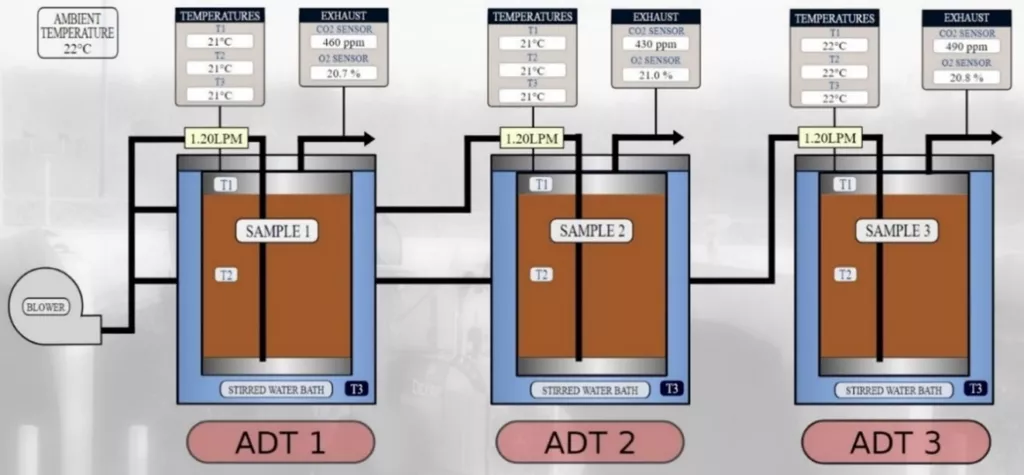

ECS conducted all tests in our in-house compost process laboratory. The tests which considered active composting environments were done in ECS’s proprietary Aerated Demand Tester (ADT) vessels. Each ADT is a sealed stainless-steel vessel nested within another steel vessel that serves as a stirred, temperature-controlled water bath. Sensors monitor the temperature in the headspace (T1), compost sample (T2), and in the water bath (T3). The airflow is controlled, and CO2 and O2 levels are recorded in the exhaust air, as illustrated in Figure 2. All sensor data is logged every ten minutes.

Phase 1 involved 7 tests on a selection of ASTM-Certified PLA products. The tests were all run for 21-days without agitation or turning (static). The active composting tests used a compostable substrate made up of 80% green waste and 20% food waste, by weight. The testing parameters were as follows:

Findings: Results from these 7 tests suggest that elevated temperatures and moisture alone have a limited impact on the degradation of the bioplastics tested. On the other hand, exposure to the active composting environment (compostable substrate mix) increased the degradation rates of the film bag, the low temperature PLA cup, and the fiber coffee cup. Overall, the degradation rates of these items appeared to increase with increased temperature. We noted the moisture levels in the ADTs were high (close to the water holding capacity of the substrate), and conditions uniform throughout the 21-day test. In practice, moisture levels tend to be lower in windrows or aerated static piles, and pile conditions are never perfectly uniform.

Photos and full descriptions of the tests can be found in the Biocycle Article.

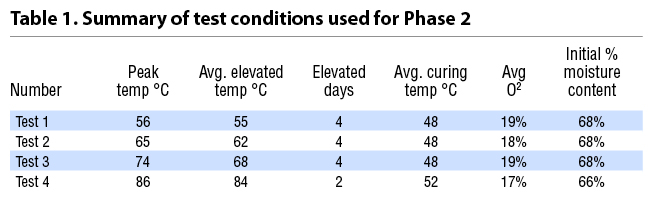

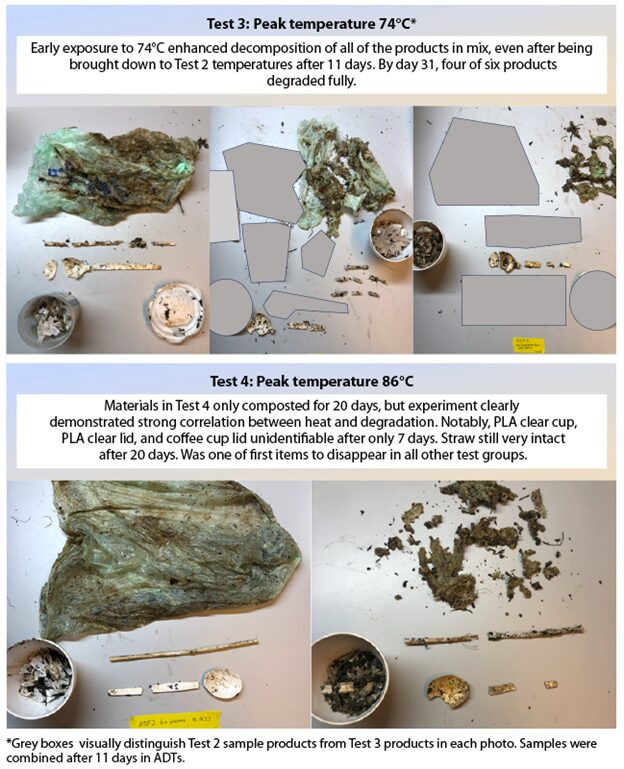

The Phase 2 tests expanded on Phase 1 Tests 5-7 and explored the effects of combining active compost biology with a range of even higher temperatures over a period of 31 days. Each of these tests utilized a wider array of certified compostable bioplastics, including some products used in the Compost Research and Education Foundation’s Field Testing Program. All of the tests were conducted in ADTs, using the same compostable substrate blend. The ADTs were programmed to maintain an early period (2-4 days) of mesophilic temperatures to encourage a pH shift to neutral.

Once this mesophilic period was completed, the ADTs reached temperatures of 56oC, 65oC, 74oC, and 86oC, respectively. Table 1, below, summarizes these conditions.

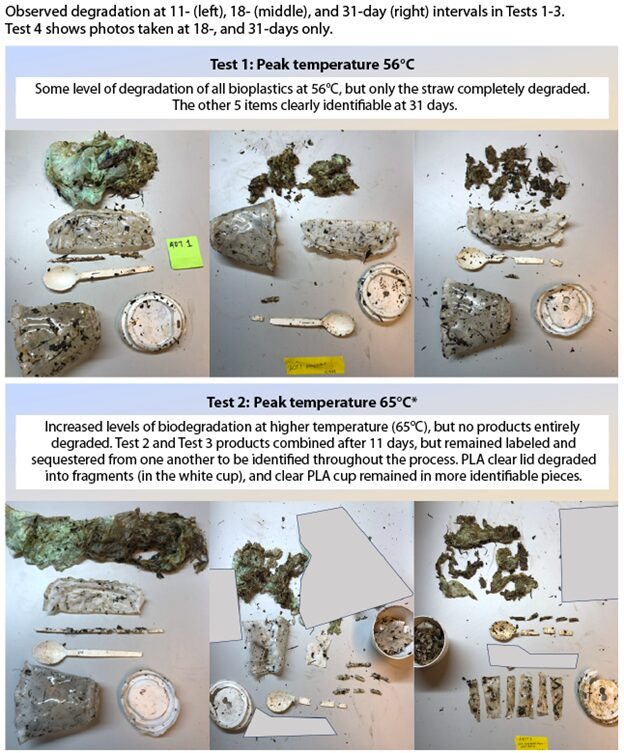

At three points in the composting process, the ADTs were opened, and the products were removed for observation and strength testing with a custom-build jig. The biodegradation results can be seen in the images below.

The ECS results from Phase 1 and Phase 2 tests indicate that there are correlations between temperature and rates of bioplastic degradation in an active composting environment. In our tests, higher composting temperatures resulted in more rapid and complete degradation of the majority of the test products. It was also clear from Phase 1 Tests 1-4 that elevated temperatures and moisture alone were insufficient to degrade bioplastics, indicating that active-phase compost biology plays a significant role in breaking down PLA-based bioplastics.

These results are of some concern to us when we think about extrapolating them to commercial composting facilities. Here are a few reasons why:

For more information and discussion of this research, please follow this link to the full Biocycle Article.