Aeration floors provide a critical role in aerated composting systems. They also are one of the most costly and challenging elements to design and build, and should be selected to meet the unique conditions of each facility. ECS has developed several aeration floor technologies, each with it’s own set of pros and cons.

In general, well-designed aeration floors should support favorable process conditions as uniformly throughout the pile as possible, including sustaining Best Management Practice levels of oxygen and temperature. When evaluating aeration floors technologies, ECS recommends considering:

Most sites composting with aerated static piles use one of the following aeration floor types:

The fluid mechanics governing friction and airflow through these aeration floors are fundamentally similar across all three cases. At its simplest, air loses pressure due to friction as it travels down a pipe. When that pipe has orifices, the pressure driving air through the orifices will vary along its length as this pressure changes. The variations of flow through each orifice is called mal-distribution. In compost aeration floors, some degree of mal-distribution is inevitable. To keep the compost pile oxygen and temperature levels within a desired range, an aeration floor should be designed to minimize this mal-distribution.

We use the term ‘sparger’ to describe the pipe used to distribute air in both above and below grade floor types. To design a high-performing sparger the spacing and size of the orifices is critical since the pressure losses through the orifices must dominate the pressure loss down the pipe, but without requiring excessive fan power. ECS has developed a computational fluid model so we can optimize the sparger design for any size pile and for any range of aeration rates (cfm/yd3). Our sparger pipe floors effectively minimize mal-distribution and economize on fan power.

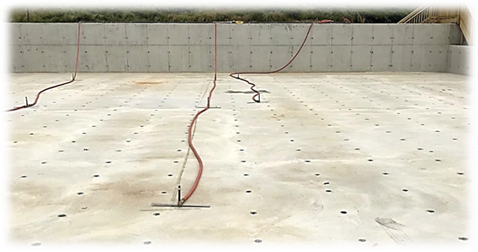

ECS trench floors are also designed to minimize mal-distribution while requiring less fan power than a sparger floor. The stainless-steel trench covers have many more small holes and operated at lower pressures than a comparable sparger floor. They achieve adequate airflow uniformity by using a below-grade pipe network to balance flows and minimize pressure losses along the trench. The same computation fluid model is used to select the sizing and geometry of the pipe network/trench/cover components that comprise this aeration floor. In both approaches, the design engineer must ensure that the pressure loss through the small orifices in the trench cover is sufficient to achieve a semi-uniform air distribution across the trench. Trench floors are generally more expensive to construct than below-grade pipe floors.

ECS aeration floors:

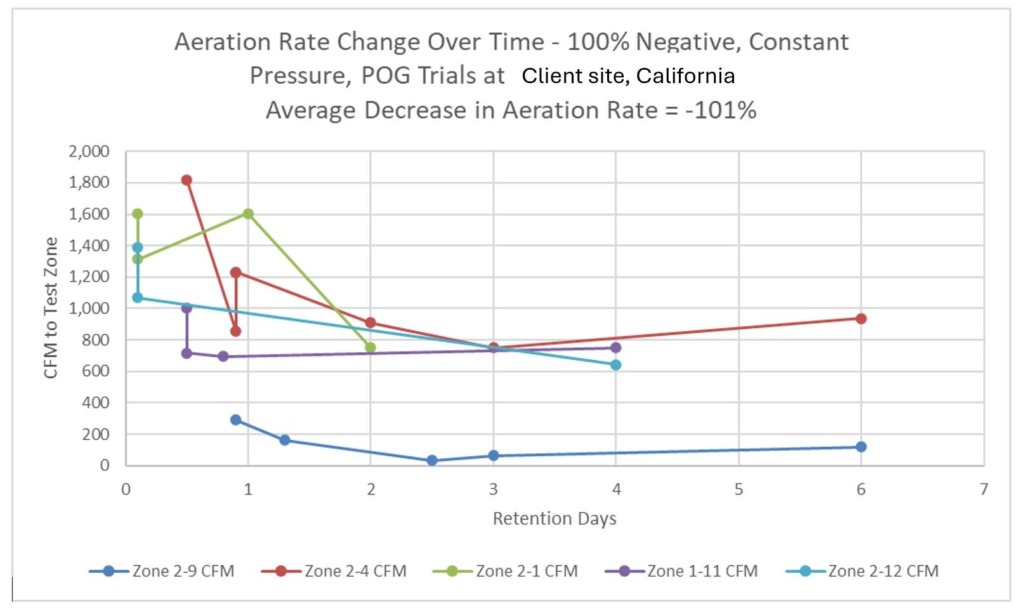

When a reversing floor is in negative mode, the fan’s suction pressure draws air down into the orifices. Compared to a trench floor, the sparger floor will have higher orifice velocities and flows, greater suction pressure, and larger orifice diameters. This makes spargers much more susceptible to plugging with negative aeration than trench floors. We have measured and observed this phenomenon repeatedly. The longer the material stays static (not moved) the more plugged the orifices become. This makes sense when one considers that the air velocity at a sparger orifice is in the same range as low end shop vacuum. ECS measured this effect at a large CASP facility near Dixon, CA that operated 100% of the time in negative while the operators were experimenting with different sparger designs (Figure 4 below). The scatter in the data is the result of the tests being designed to evaluate different orifice size/number combinations, yielding different day-by-day results. But in all cases, the reduction of airflow was large (average of 101%) over four to six days, despite the aeration source being held at a constant pressure. Given that nothing else in the system changed during the test period, the reduced airflow can only be the result of increased plugging of the sparger orifices.

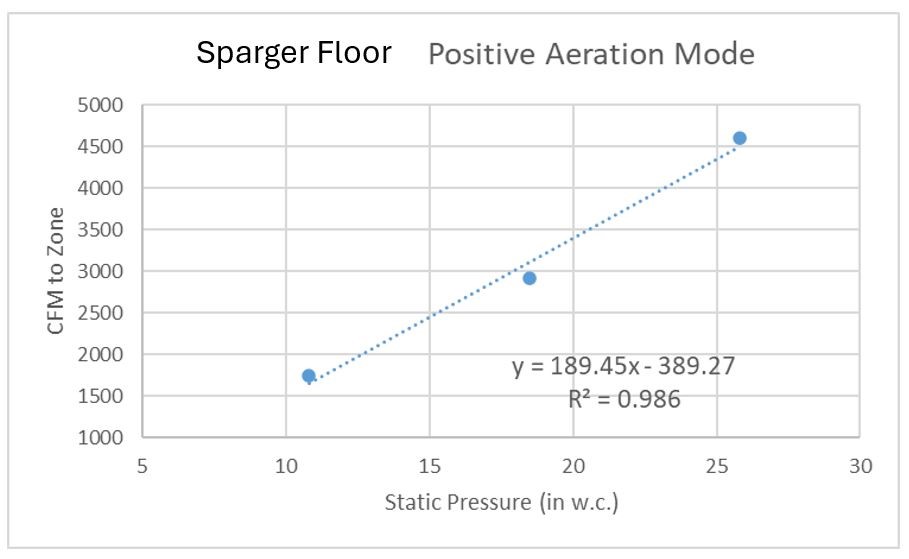

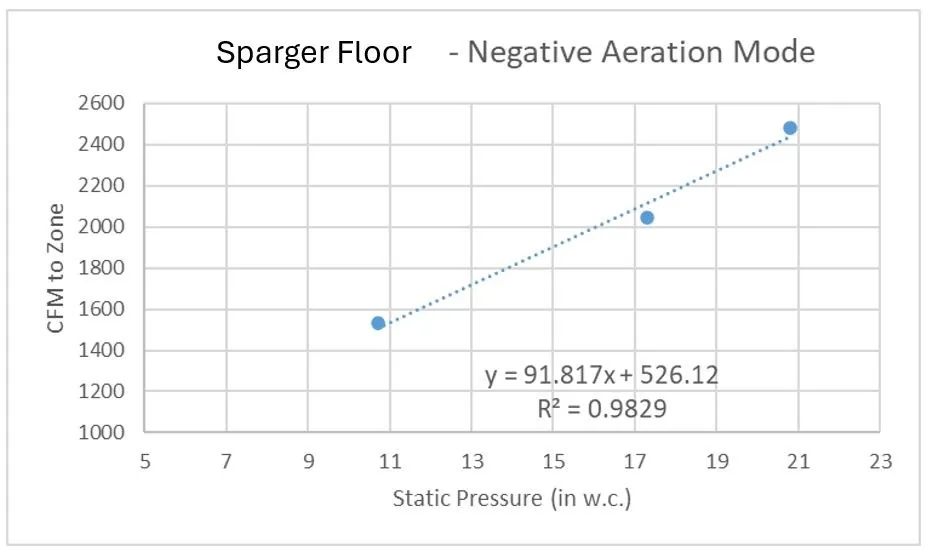

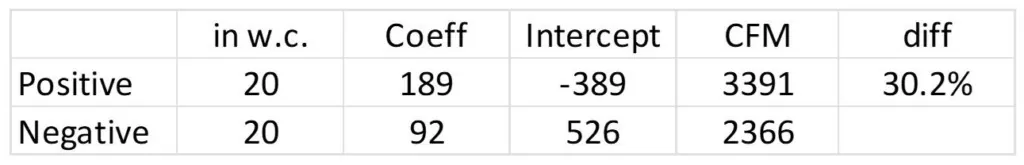

We also conducted a study at a green waste processing facility in WA, which has sparger floors and reversing aeration. At the time of the tests, the compost was turned with a CT1010 every 2 to 3 days. We tested both positive and negative mode on the same pile within 60 minutes. The resulting flow vs pressure data in Figure 5 and 6 has a high confidence linear fit which can be used to calculate and compare performance at the same operating pressure. Using a typical operating pressure of 20 in w.c. and the two linear equations, we calculate 30% less flow in negative mode than positive mode.

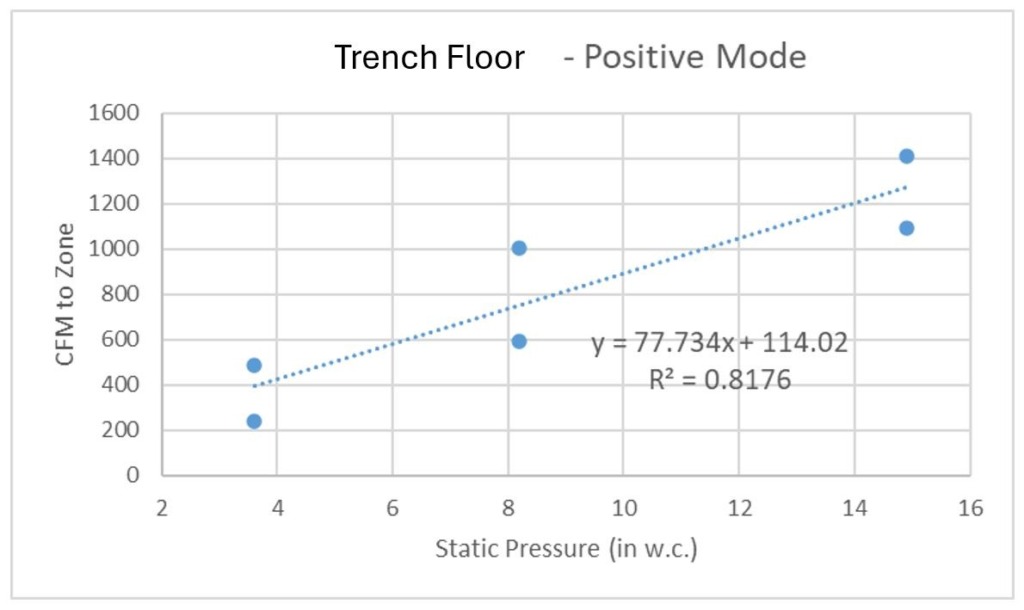

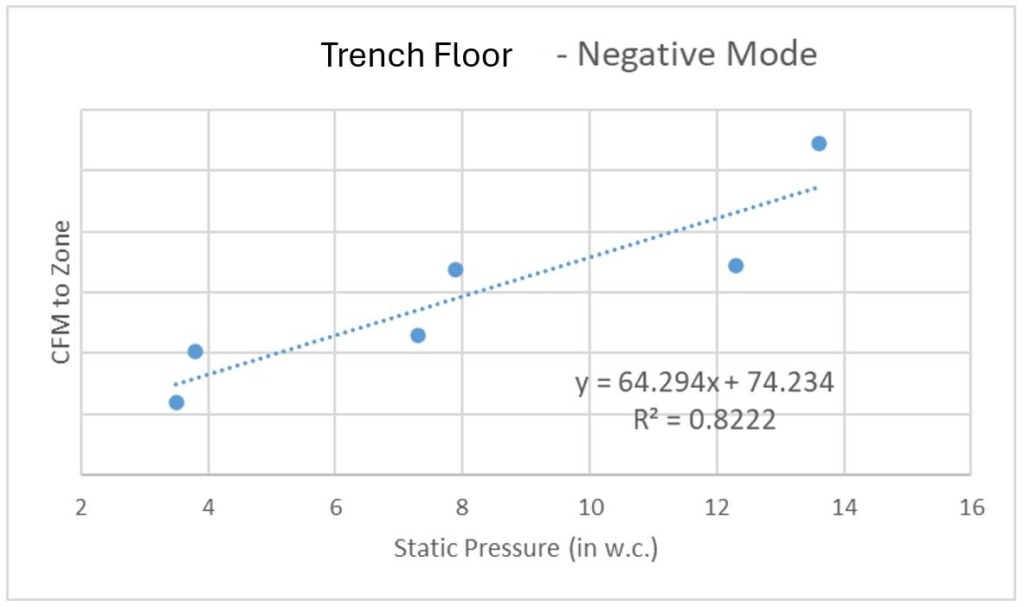

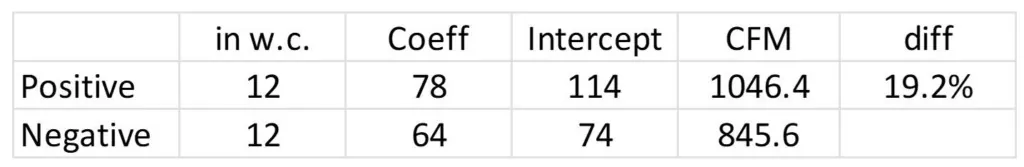

We conducted the same tests at a large reversing CASP with an trench floor at a WA based green + food waste composting facility. Figure 6 shows this data and linear fit equations. Again, we chose the typical operation pressure for the trench floor of 12 in w.c, which is much lower than the sparger floor. We calculated the expected air flow rates, finding 19.% less flow in negative mode than positive mode. This is 50% less relative loss of airflow than we measured on the sparger floor in the example above. This is due to the sparger floor pulling more particles into the high velocity flow zone in and around the sparger orifice, whereas the more numerous trench orifices have slower velocities and are more resilient to plugging.

Some vendors claim that the high-pressure capacity in a sparger floor in positive aeration can physically clear the orifices in a manner that a low-pressure trench floor cannot. ECS clients use positive aeration when emptying or filling a zone with either a sparger floor or a trench floor for just this reason. But neither floor can generate the force to lift the whole 8 – 10 ft column of compost material once in place. And once the aeration switches to negative the sparger orifices begin to plug. Operators at a large compost facility in AZ, which has a sparger floor, reversing aeration, and high-pressure fans, reported that they eventually turned the fan pressures down by half after experiencing excessive orifice plugging, high electric power consumption and uncontrolled temperatures.

ECS has delivered dozens of trench aeration floors for reversing and negative aeration systems starting in 2002, including to numerous repeat customers. The trench covers are fabricated from smooth 304 SS heavy duty plate and are recessed about 5/8” below the finished concrete surface. The covers are easily removed and replaced if damaged. Our trench covers have 30 to 40 orifices per meter and tolerate some plugging without impacting performance.

A typical sparger on the other hand has one orifice every 30” along it’s length; plug a few of these and the pile will have significant unaerated areas.

While the trench floors are not immune to plugging, when operators follow straight forward simultaneous cleaning/loading methods and create mixes that are within the BMP realm for density, moisture and structure, we observe less systematic plugging issues comparable to negative aeration sparger floors.

ECS has delivered over a dozen large sparger floors for positively aerated ASPs. They are highly cost-effective and particularly useful when a site has a modest tolerance for air emissions and relaxed stability standards for compost leaving the aerated process (single direction aeration creates a very large temperature gradient and tends to dry the feedstocks out as fast as is thermodynamically possible).

ECS has delivered above-grade perforated aeration floors to many sites in the past. However, when compared to the durability, efficiency, and performance of below-grade aeration floor types, above-grade pipe falls short. In addition to providing less even air distribution, above-grade pipes are vulnerable to cracking and warping and generally require more staff handling than either spargers or trenches. Since above-grade pipes typically must be pulled out from underneath a pile, they effectively double the footprint of each pile, making them highly space inefficient. Above-grade pipe also provides no drainage infrastructure, potentially increasing the challenge of managing pathogenic contact water (leachate).

Despite being by far the lowest initial capital cost option, many facilities find themselves spending additional money to convert above-grade aeration to below-grade aeration.

The table below summarizes the performance of the three types of aeration floors discussed here. The best floor is the one that best aligns with the project goals.

The aeration floor constitutes one of the largest single costs in developing a compost site, and can last for 20+ years. ECS has been deploying and improving our aeration floor designs since 1999. Contact us to discuss what aeration floor is best for you.

We want to learn more about your project goals. Call or email us to get started.