Since our founding in 1999, ECS has been dedicated to delivering science-based, well-engineered composting equipment designed to exceed customer expectations. Along the way, we’ve also worked to support and strengthen the broader composting community.

This page serves as an archive of key milestones and memorable experiences from our journey. Thank you for following along!

Despite 60°F rain, our trip to Vegas had lots of sunny moments. ECS’s Baraka Poulin shared updates from Washington organics laws and how these policies contribute to both increased food waste and contamination entering our compost facilities. Spoiler alert – more aeration and attention and attention to process control provide key tools for managing these challenges! Shoot us a message if we can help at your facility: [email protected]

USCC continues to set attendance records each year, and this was perhaps our favorite conference yet. We enjoyed learning from the many excellent speaking sessions as well as reconnecting with friends and colleagues. We consider ourselves fortunate to be part of such a postive industry.

Highlights inlcluded :

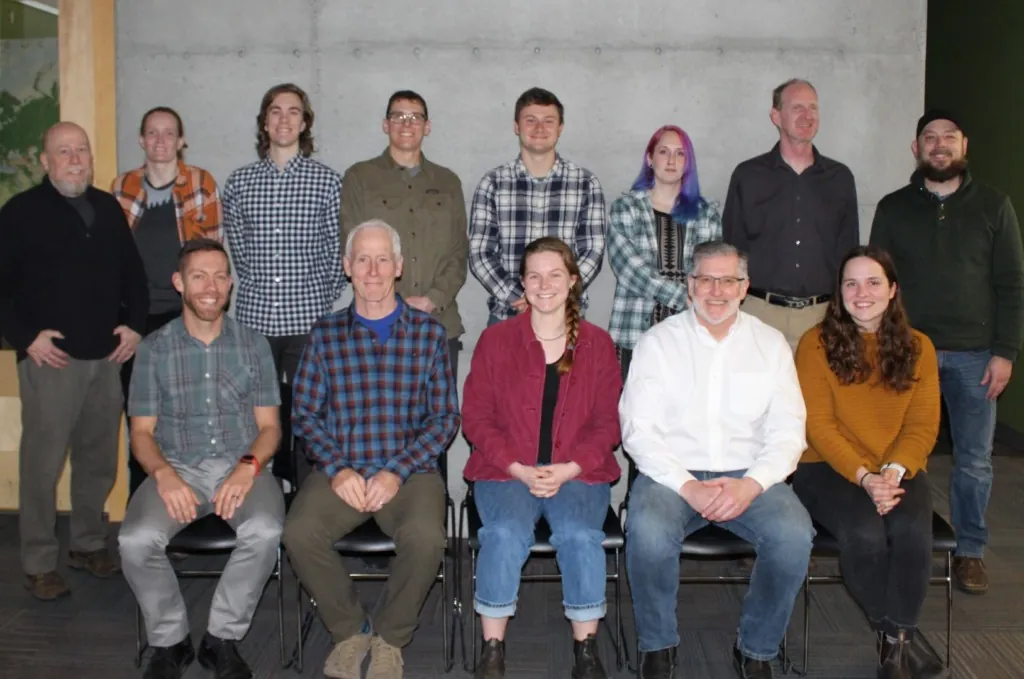

Great to see everyone at the USCC 2023 Conference!

This year’s conference was one of the best one’s yet. A few memorable moments:

We are proud that USCC recognized the Napa Recycling team’s exceptional operation and successful track record (Will Kelley accepting the award in the picture below). For nearly three years the Napa team has composted over 60,000 tpy of a wide and varying range of organic feedstocks in their ECS supplied CASP system and kept in compliance with their stringent air permit.

We would especially like to thank the Burrtec Team, who generously hosted tours at both their Agua Mansa (shown below, ECS equipment) and West Valley composting facilities.

We enjoy hearing what others in our industry are learning. We caught a few great sessions including:

Hopefully you also managed to catch our two presentations:

Lastly- congratulations to Cary Oshin’s on his retirement. Thank you for persistent dedication to improving our industry and all of the fun times!

Engineered Compost Systems team members and MTNW’s Thermal and Line Control groups gathered together to show support for the Seattle Seahawks, who are going to the Superbowl for the second time in a row. Yes, that is a manikin in the middle. That’s Newton, who took a break from thermal testing to sport Seahawks jersey #31 belonging to Kam Chancellor, a founding father of the “Legion of Boom. All over the Seattle metropolitan region people are showing their colors. Go Hawks!

Article by Anthony Adragna

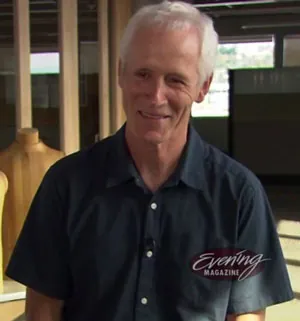

“Back in the early 1990s, Tim O’Neill and a colleague began to develop large-scale systems for the sort of cutting-edge, environmentally conscientious composting that few people engaged in at the time. Since then, as municipalities of all sizes from around the country have embraced the concept of turning organic waste into something useful, O’Neill’s Engineered Compost Systems (ECS) has become a national leader in designing large composting systems.

In 1990, communities across the United States composted 4.2 million tons of the 208.3 million tons of waste they generated. Twenty years later, more than 20.8 million tons of the 243 million tons of waste generated were composted and recovered. Washington state facilities alone processed 1.15 million tons in 2010. In 2009, about 3,000 communities in the United States had documented composting programs. Americans now recycle or compost almost 34 percent of their total waste, more than double the rate from 1990.

With greater national environmental awareness comes the need for facilities to compost waste. Launched by O’Neill in 1999, ECS has delivered more than 45 composting systems for municipalities and commercial clients in the United States and Canada.

O’Neill says ECS typically customizes facilities around two main types of aerobic composting systems. In-vessel systems are essentially small chambers that are completely enclosed. The facilities are stable and allow clients to tightly control air and temperature settings, enabling the composting process to happen more quickly. Since the system requires a structure to be built, the costs are higher than for the other ECS method, known as an Aerated Static Pile or ASP. In this method, a large mound of waste outfitted with a system that enables air to flow through the pile. O’Neill says the floors of the facilities are customized for clients, but ECS has found a way to build them more economically than many competitors while retaining rigid temperature and air controls.

“Most of the technology-based compost equipment companies are single technology,” O’Neill adds. “They try to fit their vision of the world to everybody’s reality. We take the opposite approach. You can see 40 different clients, each one with a somewhat different design.”

Interest in constructing systems comes from both the public and private sectors. Public clients range from small towns to large municipal entities handling the composting needs of several cities. No matter the client, O’Neill says the sales process is slow, often lasting from one to five years.

After a potential client expresses interest in building a system, ECS develops a preliminary design and builds an economic model. One third of all prospective clients continue on to a pilot system, which enables both the client and regulators to get a sense of what the system will do. The pilot programs are smaller than the full-scale systems and typically operate for six months.

O’Neill says ECS’s business grew during the past several years, despite the difficult economy. “The first six years were pretty slow growth,” he says. “We were break-even the whole time. Anytime we made money, we turned it around and put it back into product or marketing development work. The last four or five years, it’s been quite strong and quite steady and on a growth path.”

Eric Myers, director of organic recycling operations with Waste Management, is a satisfied ECS customer. Waste Management installed two ECS systems in Florida and is extremely pleased with the results. “ECS has been a great partner in developing these facilities,” Myers notes. “Both facilities are ramping up the volumes we are recycling, and the systems are performing well and as designed.”

In Washington, ECS has installed systems in Spokane, Everett, Tenino, Westport, Walla Walla, Omak, Stanwood, Lynden, Arlington, Ocean Shores, La Conner, Port Angeles and Puyallup. Other major systems are operating in Okeechobee, Florida; Dixon, California; and West Yellowstone, Montana. A team of 10 employees designs the technology, writes the necessary software and builds the controls and instrumentation from ECS’s offices in Seattle’s Magnolia neighborhood.

As both federal and state regulations continue to change, ECS has maintained strict environmental standards about the air pollution, odor and surface water at its facilities. With new regulations and standards likely, more communities have been willing to invest in composting systems.

Though industry growth remains slow, O’Neill says he is content with the size and volume of business. “Slow growth is great,” he explains. “We have no debt, we’re in the black and that’s not a bad place to live. I have no aspirations to grow into a large company and sell it. My employees put in a lot of work to get it to here, and I’d like them to continue to have a great place to work.” “

Tim O’Neill discusses thermal manikins made by Engineered Compost System’s parent company, Measurement Technology Northwest (link removed).

“Tim O’Neill and Engineered Compost Systems take the “ick” out of organic waste” says the subtitle of the article written by Matthew Halverson.

Want to know the details? Go to SeattleMet’s website to read the full article.

The ECS team and their sister company, MTNW, have pooled their resources together and raised $2,680 to donate to the American Red Cross Hurricane Relief.

After Typhoon Haiyan swept across the Philippines on November 8th, 2013 over 10 million people across 36 provinces were affected by its disastrous forces, thousands were displaced and left in need of shelter, food and clean water.

The American Red Cross is working directly with the Philippine Red Cross, who has been leading this response effort, and is in charge for providing shelter, food, and water, and distributing relief supplies. We hope that our contribution will aide in this global effort.

Click here to read more about Red Cross’ efforts & support.

Our fearless Director of Business Development, Steve Diddy, was recently published in the March 2013 issue of Waste Advantage Magazine with the first of a two-part article “Evaluating the Viability of Developing a Composting Facility.” Part 1 outlines a three key step Pro Forma Analysis process to evaluate and plan development or expansion of a composting operation. As Steve explains in the article, it is wise for a prospective facility owner to follow this process to become very clear on how such a development will meet their business objectives. The May issue features the Part 2 article describes what it takes to successfully build or expand a commercial composting facility.