The main objective in an Engineered Compost Systems feasibility analysis is to help our customers identify a potential business model. This tool can either cast a vision to work toward, or identify that a project does not make sense to pursue. While of course we hope to generate projects- we see both outcomes, and both provide valuable insights to our clients.

Since 1999, ECS has worked with a wide variety of clients, in different geographies, with unique regulatory conditions, and a diverse array of feedstocks. Our first step in the feasibility process revolves around understanding the project drivers and discussion what success looks like. The following topics are frequently analyzed with our feasibility studies:

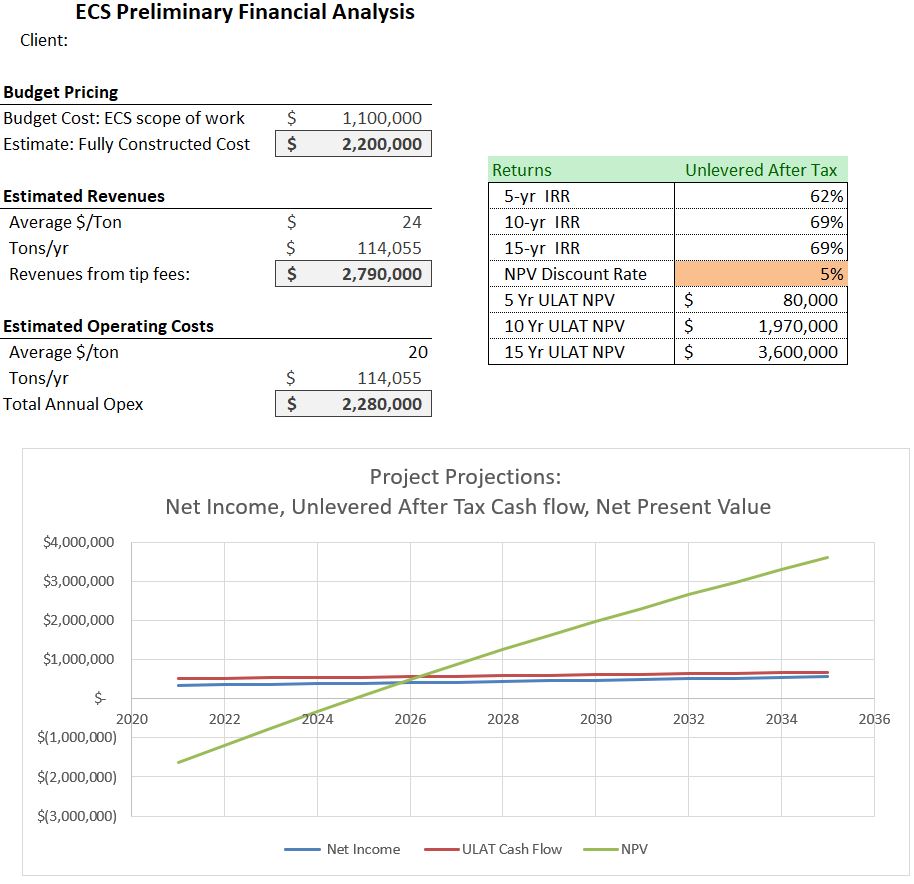

ECS offers a basic financial analysis service to help customers determine go/no-go on a project. This tool enables collaboration on key assumptions, and outputs some common criteria such as internal rate of return and net present value for the project.

This simple approach focuses on the high impact variables, and enables the team to easily model scenarios to see if a project might work. We find this process incredibly valueable early in the process – because if the team is unable to make a business case, this low cost tool can help avoid sinking money on a doomed project. Conversely, and more often the case, this tool helps align the team on a reasonable basis of design, with key project variables at the forefront over everyone’s mind.

The analysis greatly assists those that are new to the compost industry that are trying to determine if their unique application or opportunity has the solid foundation for a sound business; and, those currently in the compost industry that are trying to determine if a new process technology is appropriate (upgrading from windrow to in-vessel or ASP) and if so what type is appropriate.